Where’s the value in returnable asset tracking? That’s the million-dollar question – quite literally when it comes to returnable transport items (RTIs). At a typical unit cost of $200 to $5000, RTIs are far from cheap, mostly with good reason, as they’re built for long-term use. But when containers are lost or stolen, and never return for reuse, these valuable assets can become a liability. So how can smart asset tracking software help? And what kind of returns can you expect on your investment?

Find your RTIs and you’ll find the ROI

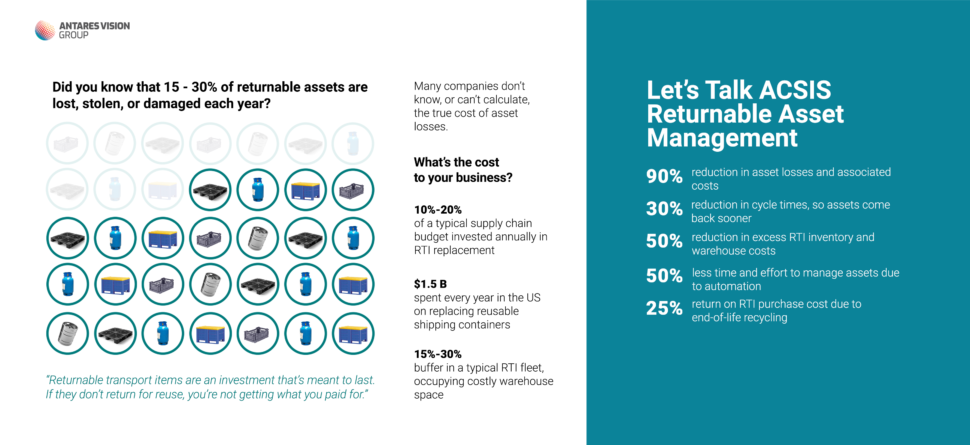

The most immediate returns on solutions like Returnable Asset Management are upfront savings on asset replacement costs. When you consider how many shipping containers are in use at any one time, and that 15-30% typically go missing, the enormity of these savings really starts to add up.

Take one of our customers, a multinational baking company that transports its goods in around 8 million baskets. Bread baskets are a relatively low-ticket item but when 30% go missing, at $10 a piece, you’re looking at replacement costs of $2.4 million. With ACSIS Returnable Asset Management, each basket is now tagged and tracked as it moves through the supply chain. And first-year savings of over $7 million more than pay for the initial software investment.

Offloading excess inventory

But the savings don’t stop there. Most firms overstock RTIs by 15-30% to avoid disruption when they inevitably go missing. Say the same baking company keeps 2 million baskets on reserve. That’s $20 million worth of assets before you even start to consider warehouse and maintenance costs. With effective asset tracking software, you can expect a 90% reduction in RTI losses – and of these far more will live a long and useful life. With a more reliable and predictable asset fleet, you can safely minimize costly buffer stock.

But there’s more to ROI than simply avoiding costs. Today’s automated tracking software also repays your business in time, replacing costly and laborious manual tracking processes. Companies can expect a 50% reduction in time spent manually managing assets. Optimized labor costs and better use of talent bring savings and efficiencies far beyond the simple pallet.

Small cog – big impact

This is where returnable asset tracking really proves its worth, keeping the wheels turning in your supply chain operations. The humble RTI is just a cog in a very big wheel. But if that cog stops moving, and isn’t there when the wheels start to turn, there are knock-on effects for production and distribution. Production delays, missed shipments, the list goes on. What you can’t see, in this case, really can hurt you.

In contrast, when returnable assets are tracked in real time, you gain a valuable window into supply chain processes. Together, every piece of data paints a detailed picture that can be used to enhance efficiency across the entire supply chain. Improve inventory accuracy, enhance forecasting, and optimize planning – all while reducing your environmental impact.

Doubling down on visibility

But what about the products or materials your RTIs are carrying? Can you record a container’s contents – and does it even matter? We believe it does and experience has shown that customers get more value from a dual approach, linking returnable assets with their specific cargo. Think of RTIs as a kind of proxy for your products. By assigning product attributes, such as temperature or expiry date, you get far richer data on the product journey. With this granular level of supply chain visibility, you can uncover inefficiencies and take proactive steps to optimize operations.

But – and it’s a big but – to reap the true value of returnable asset tracking, you need a solution that can integrate with all of your supply chain partners, no matter what technology they’re using – or choose to use in the future. Cloud-based solutions like Returnable Asset Management integrate seamlessly with any data collection technology or device, syncing in real time with any ERP system. Harvesting data in the cloud and applying advanced analytics, you get actionable insights that turn RTIs into valuable supply chain assets.

To explore the full value of intelligent asset tracking, reach out to our team today. We’ll help you find a solution that delivers maximum returns.